"The production site is fully started and the equipment is running at high speed"

Recently, Xiamen XieFa Vacuum Forming Packing Co., Ltd.has been working overtime to produce a batch of customized blister PP trays for food industry customers . The large quantity and special specifications of this order have put higher demands on our production equipment and process flow. In order to ensure on-time delivery, we operate at high standards from management to workshops.

This customer is a well-known domestic cold chain food brand and has strict requirements on the quality of packaging pallets, including:

In this project, we fully utilized our one-stop blister molding manufacturing capabilities . The specific process is as follows:

Our engineers design CAD and customize blister molds based on the customer's product size and loading requirements. After multiple rounds of proofing, we ensure that the mold is accurately formed, the slots are matched, and the edges and corners are smooth.

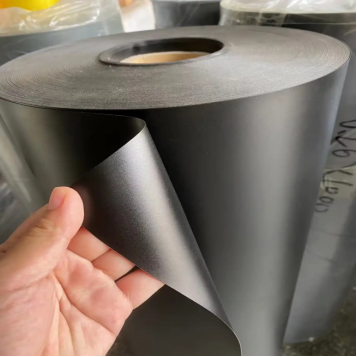

It uses brand new food-grade polypropylene (PP), which has the characteristics of high purity, no odor, high temperature resistance, and no precipitation , ensuring safe use.

The fully automatic high-speed blister machine runs 24 hours a day, with precise temperature control, stable adsorption, full tray formation, neat edges, uniform thickness, and supports customization of multiple colors and thicknesses.

Each pallet undergoes high-precision cutting and punching processes, and is subjected to compression testing, thickness testing, and size sampling by quality inspectors to ensure consistency and durability.

Finally, the pallets are automatically stacked, organized and packaged, labeled with customer labels, and loaded onto trucks for shipment.

Supports multiple specifications customization : from small food box trays to large-size industrial packaging trays, flexible response

Large-volume delivery capability : daily output reaches hundreds of thousands of pieces, with stable and controllable delivery time

Full quality control tracking : production batches are traceable and exception handling is fast

Environmental protection concept leads : PP material can be recycled and reused, promoting the development of green packaging

At present, 60% of the production of this batch of customized pallets has been completed, and it is expected that all deliveries will be completed this weekend. The customer highly recognized the quality and delivery efficiency of the first batch of samples, and the two parties have started further negotiations on the next stage of cooperation.

Welcome more customers from the food, catering, agricultural products, medical industrial packaging and other industries to discuss customized projects. We will tailor the most suitable plastic pallet solutions for you.

If you need or intend to cooperate with us, you can contact us

Email:[email protected]

Phone:+86 13959219086

Whats'App: +86 13959219086

Hot News

Hot News2025-09-09

2025-07-04

2025-06-05

2024-12-16

2024-12-16

2024-12-16